Enhancing Operational Flexibility with Our Components for Winches

Umbilical winch systems are critical for oil and gas operations in both offshore and onshore, enabling the controlled winding and releasing of hoses and equipment. These systems demand precise, high-pressure fluid transfer and reliable electrical or optical connections to ensure seamless performance.

Penlink’s specialized rotary unions and winch slip rings are engineered to meet the rigorous demands of umbilical winch applications. With pressure capabilities exceeding 20,000 PSI (1,380+ BAR) and a variety of electrical and optical passage options (winch slip rings), our components deliver robust and adaptable solutions. Whether for bulk transfer, fuel dispensing, or high-pressure swivels, our products are tailored to fit customer requirements.

By integrating directly into umbilical hose reel systems, our rotary unions and winch slip rings enable reliable and efficient operations in even the most challenging environments. Penlink’s commitment to quality and innovation ensures that your umbilical winch systems perform optimally across all applications.

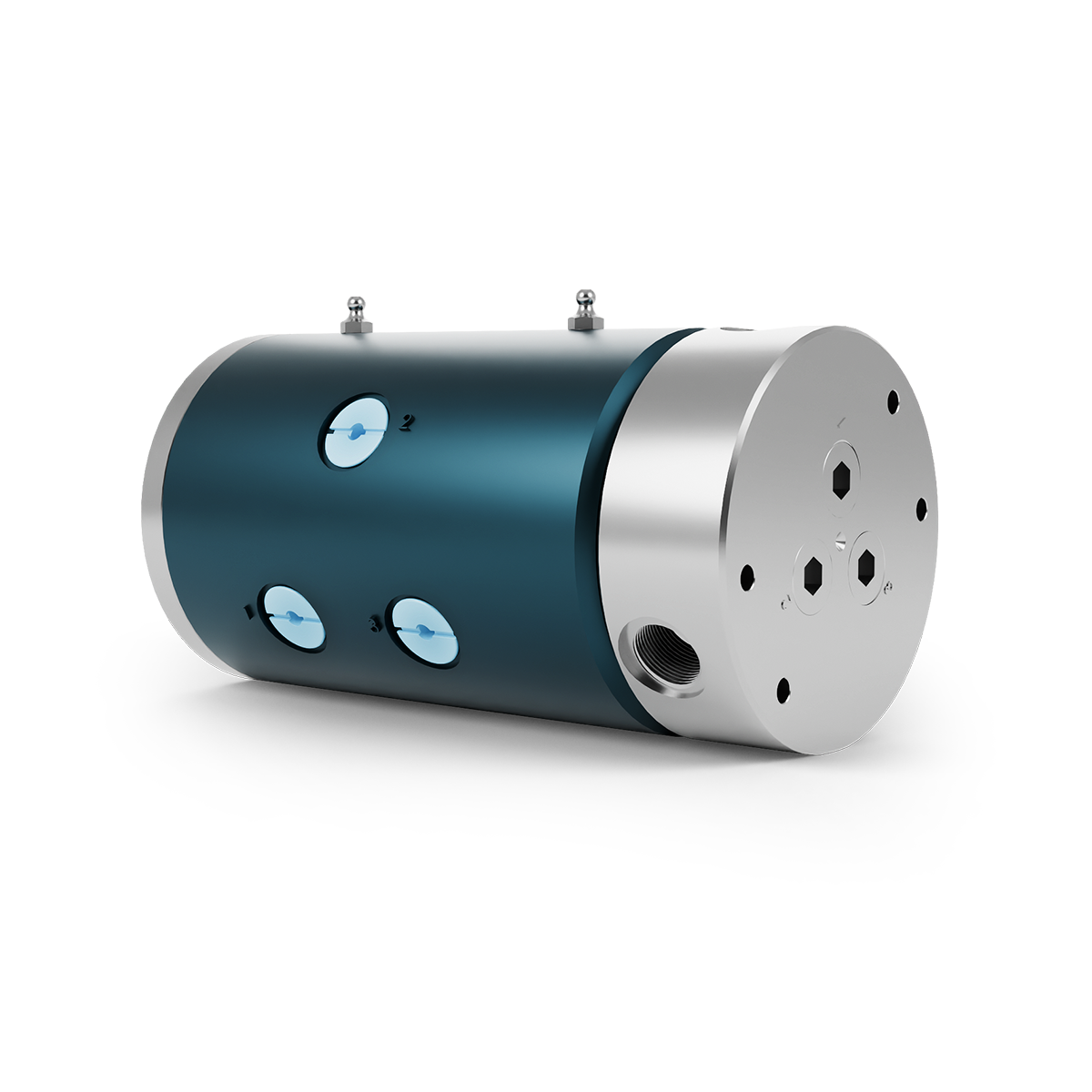

Rotary Unions for Winch Systems

Penlink provides cutting-edge rotary unions for winch systems, enabling reliable hose winding and operational flexibility.

With configurations for high pressure, bulk transfer, and fuel dispensing, our solutions are designed to meet the unique demands of your offshore or onshore operations.

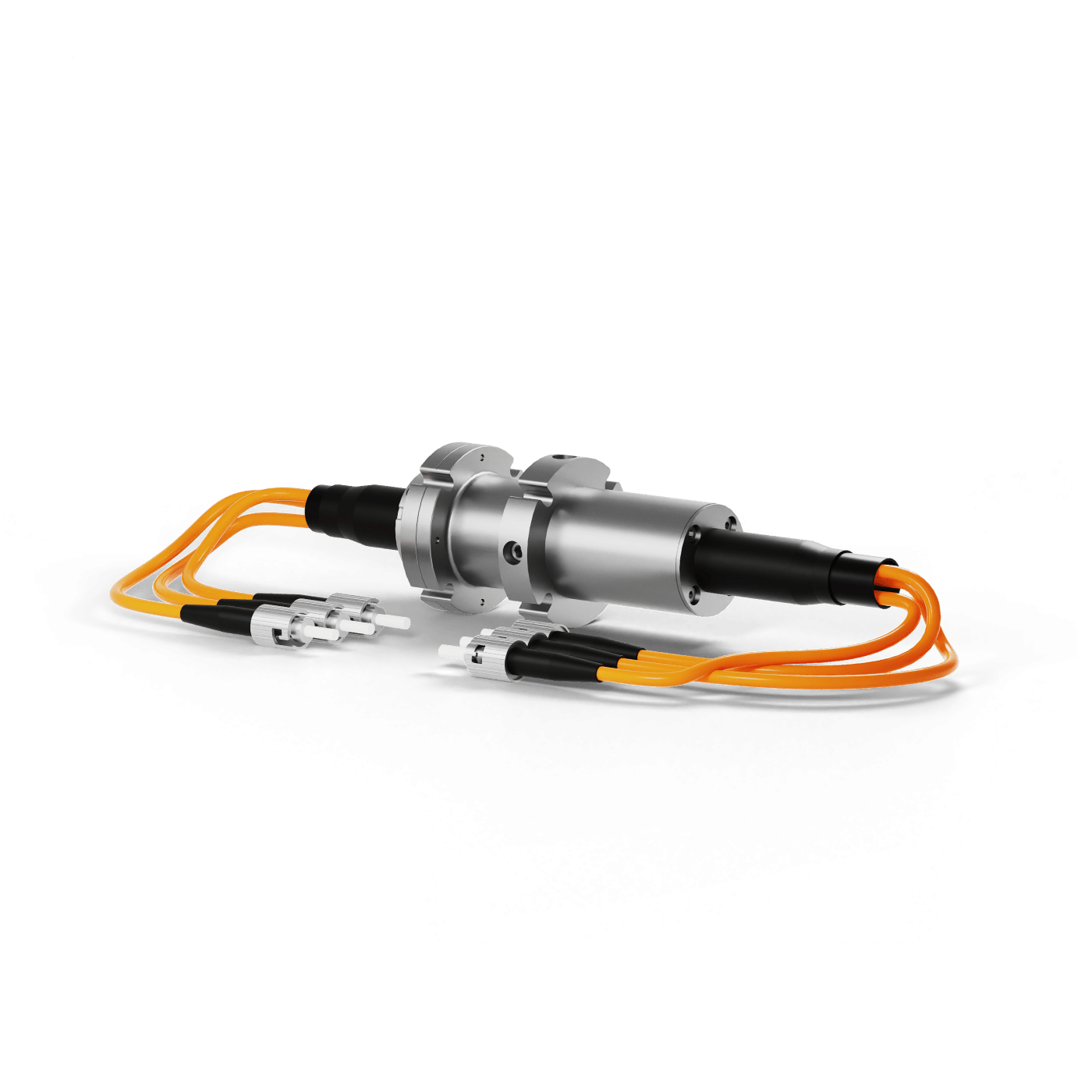

High-Performance Fiber Optical Rotary Joints for Winch Systems

Our fiber optical rotary joints are built for winch systems, ensuring stable, high-speed data transmission during continuous rotation in harsh offshore environments. With low signal loss and a compact, customizable design, they integrate easily into winch setups and support reliable communication between topside and subsea equipment.

Talk to Us

We don’t just supply components—we deliver engineering confidence. Our team works closely with OEMs, system integrators, and technical teams to ensure every component meets your performance, safety, and reliability requirements.

Looking for a solution that fits your application? Contact us today to learn more or request a quote—either by filling out the form or by emailing us at info@penlink.se.