Take Complete Control Over Position, Velocity, and Current

We offer a wide variety of EtherCAT and CANopen slave motor controllers and drives, as well as any other motor control product your particular application may require. The servo drives are designed with focus on specific applications where their performance, miniature size, and fast communications provide the best motion control experience.

Our range of DC Servo Drives can support all types of communications but our focus is on EtherCAT for high-performance servo drive systems and CANopen for lower cost distributed controls.

DC supplied servo drives are the best option for multi-axis distributed motion control applications. The dc bus reduces wiring costs and energy saving while allowing for integrating the servo drives close to the actuator.

- Most compact Servo Drives on the market

- EtherCAT, CANopen and Serial Servo Drives

- Highest Efficiency and Performance

Denali Serie – The World’s Smallest Servo Drives

Discover the Denali Series, the world’s smallest servo drives, perfect for compact integrations without sacrificing performance. With 99% efficiency, low heat emission, and negligible EMI, Denali ensures optimal performance and responsiveness for critical applications.

Boost your system with Denali’s superior power management, featuring fast current and servo loops with PWM frequencies up to 200 kHz. Designed for easy integration and industrial safety standards, Denali supports dual loop position control with EtherCAT and CANopen communication options.

Unleash Precision and Power with the Everest Series

Experience the pinnacle of motor control with the Everest Series, offering the world’s smallest servo drives. The Everest Core module delivers up to 99% efficiency, minimal heat dissipation, configurable current ranges, and high-speed SPI bus communication.

Its compact design allows for easy integration into your PCB, ideal for multi-axis applications.

Everest NET and XCR models provide CANopen and EtherCAT communications for distributed control. Everest NET ensures low latency and easy integration, while Everest XCR, the smallest servo drive in its power range, comes ready to use with connectors for seamless system integration.

Both models support high-speed SPI bus communication and meet industrial safety standards, ensuring top performance and reliability.

Unleash Unmatched Efficiency and Performance with the Capitan Series

Designed for demanding motion control applications, the Capitan Series offers best-in-class efficiency and performance. With CANopen and EtherCAT communications, and a bus latency down to 2 cycles, Capitan ensures maximum responsiveness.

Its ultra-compact design, just 8 mm in height and 18 g in weight, allows for seamless integration.

Capitan’s superior power management, with efficiency up to 99% and low standby power consumption, sets new standards in servo drive technology. Fast current and servo loops with PWM frequencies up to 200 kHz deliver exceptional performance.

Multiple integration options ensure quick start-up and easy integration, while meeting industrial safety standards with integrated STO inputs rated to SIL-3 PLe.

Precision and Performance with Our Servo Drives

At Penlink, our servo drives are engineered for specific applications where their exceptional performance, compact size, and rapid communication capabilities deliver the ultimate motion control experience.

For more information, get in touch with our sales team. We will help you find the right solution!

Servo Drive Technology

What Is A Servo Drive?

A servo drive takes the command signal for position, velocity or current and adjusts the voltage and current applied to the servo motor based on closed-loop feedback. A servo drive is an element of a motion control system which includes a servo motor, servo drive controller and feedback element, usually as part of the servo motor. However, servo drives can have many names: servo amplifiers, motor drives, motor controllers or even just drives.

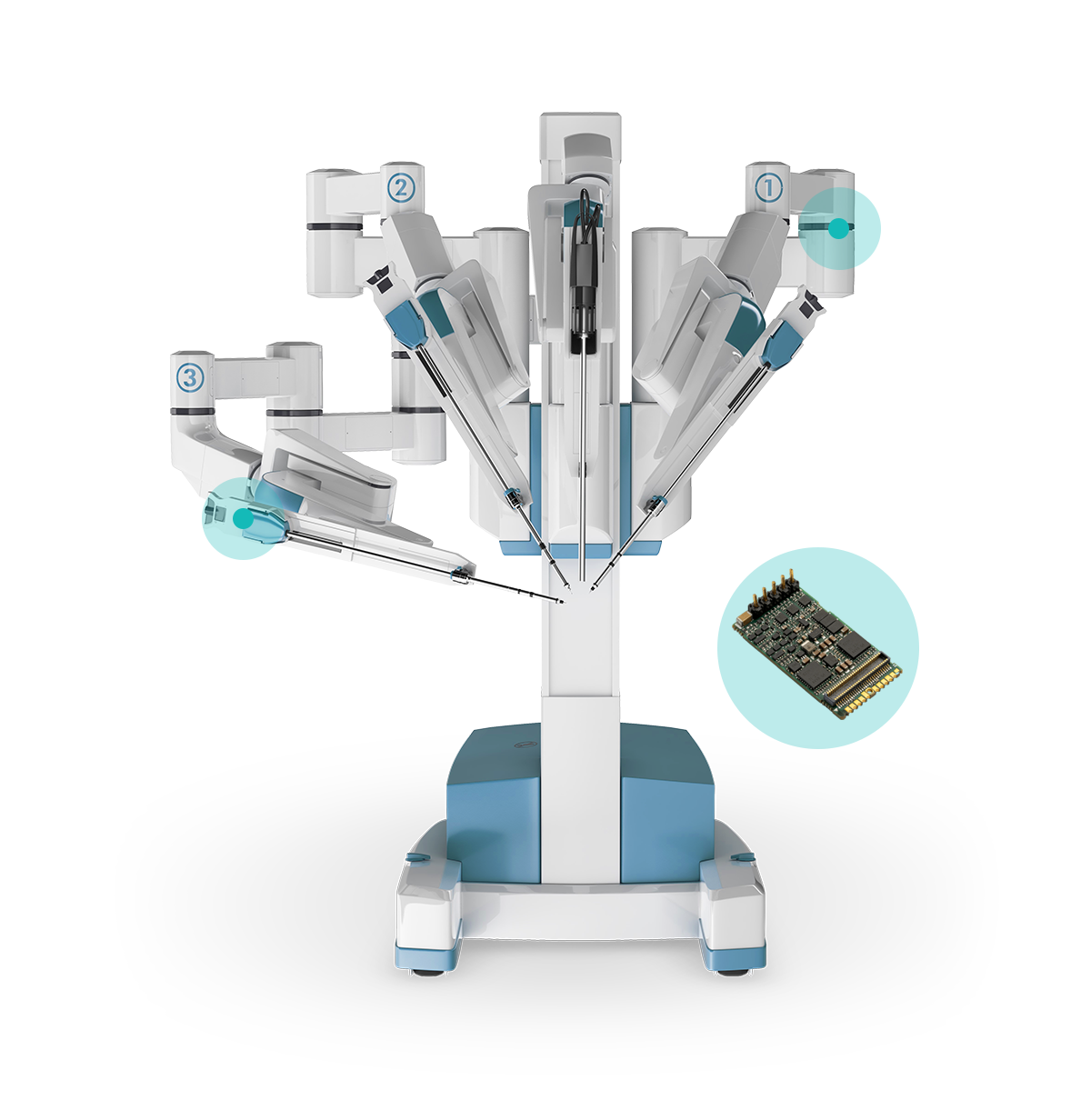

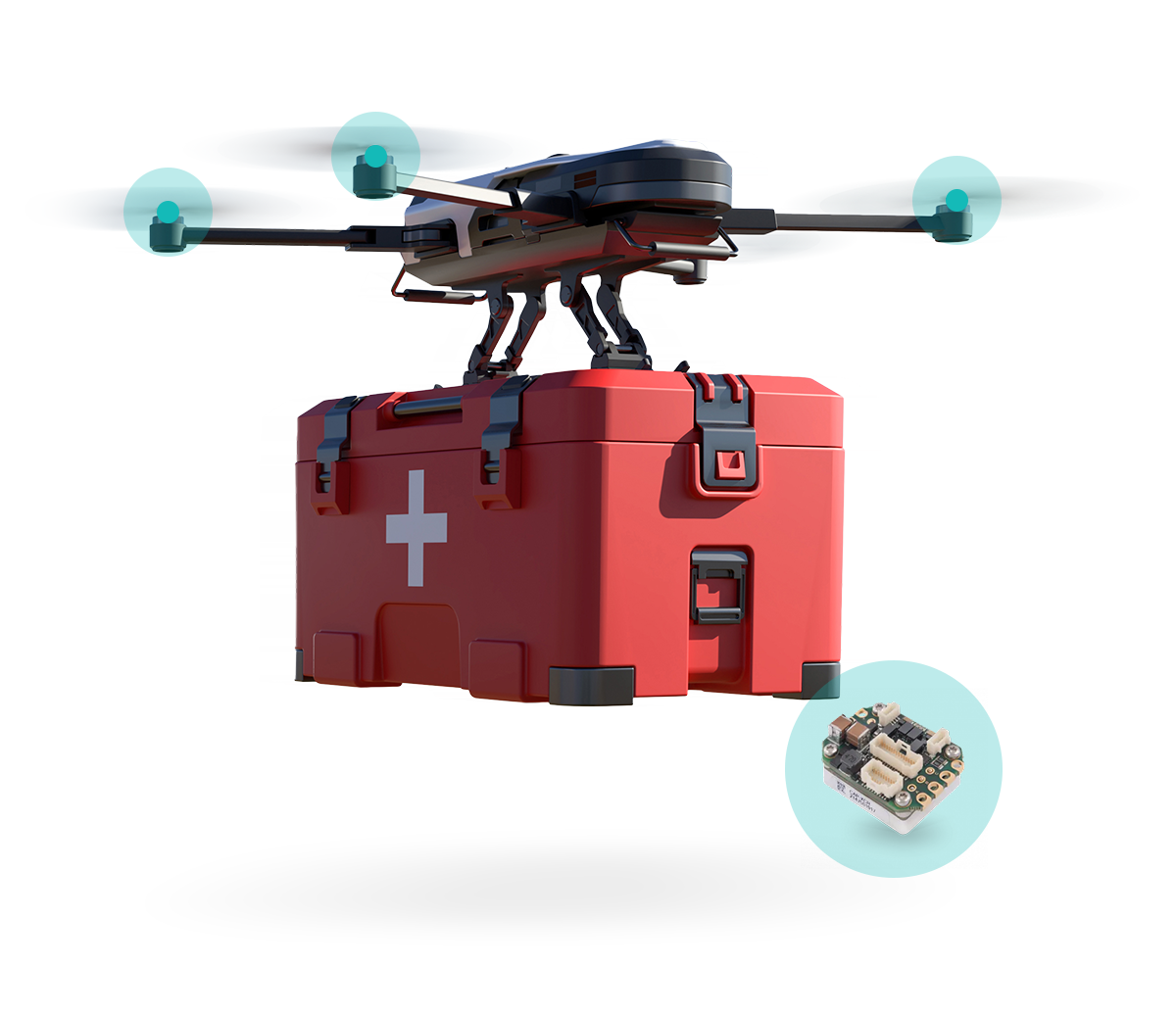

How Can Our Servo Drives Help You

We help engineering teams deliver better robotics, satcom, and medical products through the design and manufacturing of highly optimised, advanced motion controls and servo drives. Our customers are at the center of our company and we support them through a network of global engineers and partners.

We understand that finding the right motor controller is not always easy. Most off-the-shelf controllers available in the market where designed focusing only on industrial applications trying to cover as much feedbacks, communications and applications as possible. This makes this servo drives bulky, slow in performance, and hot. While this may not be a problem when a servo drive is fitted inside a cabinet with dedicated cooling, this is a major issue with new applications requiring highly integrated motor control solutions.

Our servo drives are optimised to provide the lowest heat dissipation, smaller size possible, and lowest latencies in order to enable the next generation of robotics applications.