Configure Anything from Data, Signals, Power To Flange, And Beyond

Our standard range of slip rings can be configured to suit your application’s requirements. It is possible to modify the current capacity and signal type transmitted through the slip ring, integrate the electrical slip ring with optical or fluid rotary joints, or even combine it with an angle transducer. Additionally, we can modify the slip ring with mechanical flanges and connectors.

By modifying our standard slip rings, we can offer a solution that suits your application and fulfills your requirements. Get in touch with us today to explore your possibilities, as they are endless. We work hard to bring you the very best quality that will last.

- Different Flanges

- Power and Data Signals/ Properties

- Cable Length and Protection

- Housing Material

- Through Bore/ Hollow Shaft

- Ingression Protection, High IP-Ratings

Transfer Options

We offer a wide range of video signals, as well as data bus systems such as Profinet, Profibus, Ethercat, and so on. We also offer options to transfer RF signals.

Housing, Material, & IP-Rating

Choose between plastics, aluminum, steel, or stainless steel for the housing. IP ratings up to IP67 for dust and water resistance.

Circuit Rings

The circuit rings are constructed with alloy and with an option of gold-plated conductors. Circuits can be connected to achieve the specified current within the slip ring.

Through Bore/Hollow Shaft

Through bore is available up to 500 mm. Penlink will support finding the best possible slip ring setup. Having a thorough bore opens up a wide range of installation and integration possibilities.

Connectors

All available connectors on the open market can be fitted to the slip ring circuits. Connectors can also be built into the slip ring to get an easy-to-replace design.

Flanges

Can be custom-made to fit the customer’s interface. There is no limit to how the flange can be designed. We will design the slip ring shape to meet your requirements.

Modified Standard Slip Rings

Earlier Projects

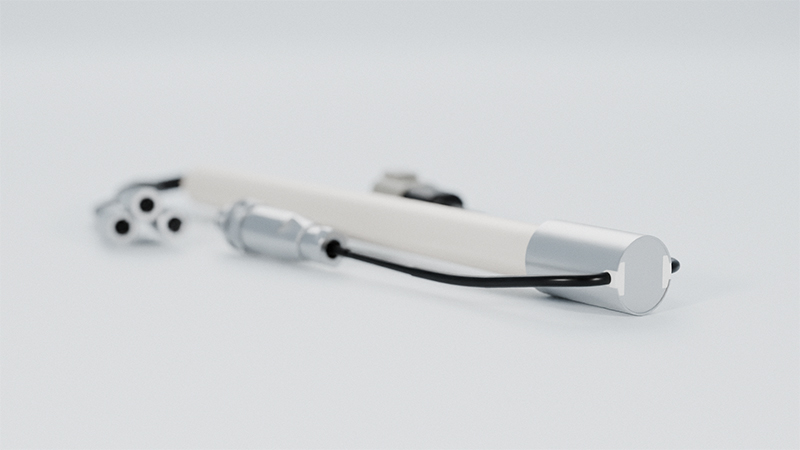

Slip Rings for Winch Systems

We design through bore slip rings with integrated fiber optical rotary joints, tailored specifically for winch systems. These cutting-edge slip rings facilitate seamless electrical and optical transmission, ensuring continuous power, signal, and data flow between stationary and rotating parts.

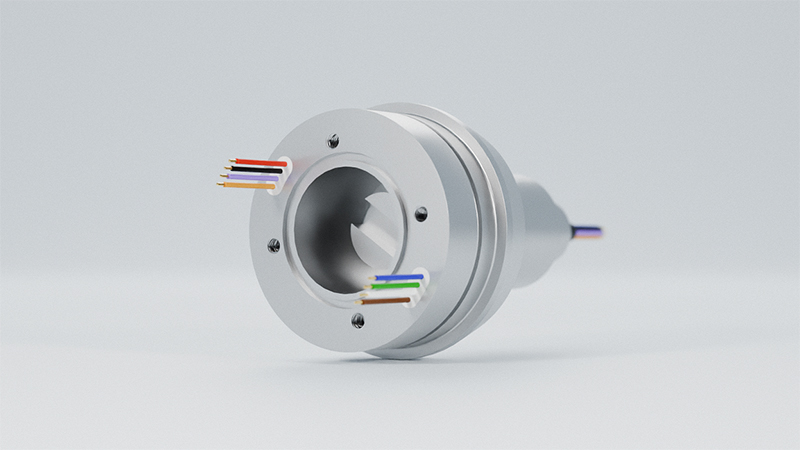

Encoder Fitted Slip Ring

We engineer compact slip rings with modified housings to accommodate small encoders for accurate position sensing. These advanced slip rings guarantee flawless electrical transmission, maintaining uninterrupted power and signal flow between stationary and rotating elements. The integration of the encoder enhances the precision and dependability of position sensing, making them ideal for applications requiring meticulous control.

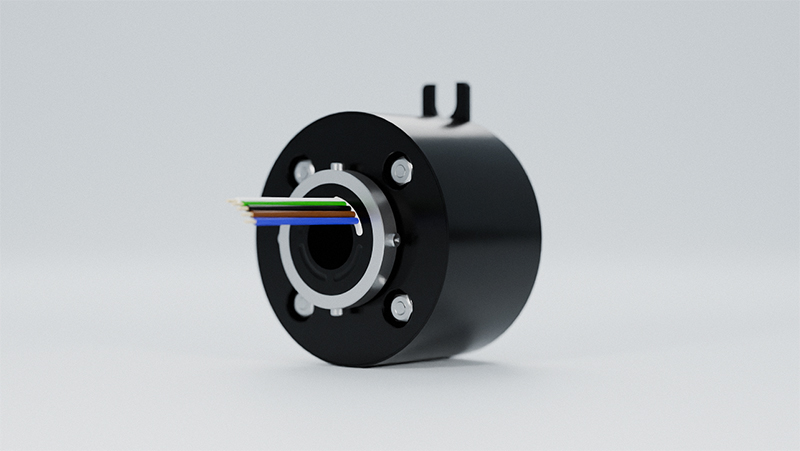

Slip Rings for OEM Manufacturers

We develop modified standard hollow shaft slip rings for OEM manufacturers of packaging machines. These innovative slip rings ensure flawless electrical transmission, providing continuous power and signal flow between stationary and rotating components.

Our custom designs significantly improve the efficiency and reliability of packaging machines, allowing for precise control and uninterrupted operation.

Slip Ring for Excavator Tools

We design specialized slip rings for rotary tools on excavators, aimed at transmitting essential safety signals during operation. This model features isolation tubes from the stator side, ensuring optimal performance and safety.

Slip Ring for Hydraulic Grippers

We design and implement hydraulic slip rings for hydraulic grippers. This innovative solution integrates both electrical and hydraulic transmission, ensuring continuous power, signal, and fluid flow between stationary and rotating components.

Let's Talk

Share Your Project with Us – We’re Excited to Learn More!

Reach out to us, and we’ll try to respond within 24 hours. If you have not received an answer after 24 hours try calling us or e-mail us directly at info@penlink.se – sometimes form submissions get stuck in the spam filter.

For urgent matters, please call us right away at +46(0)84011010 or send us an e-mail.