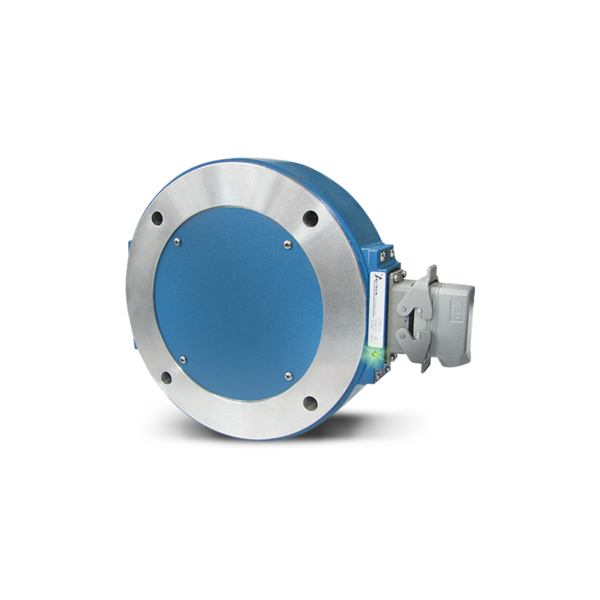

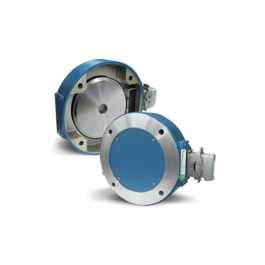

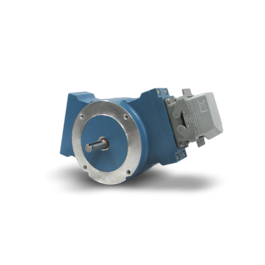

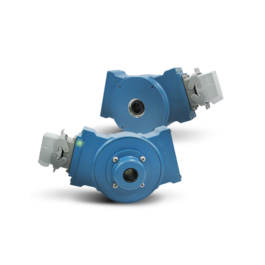

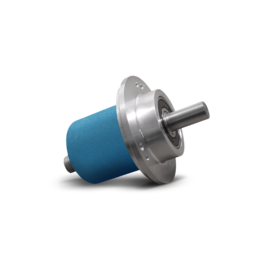

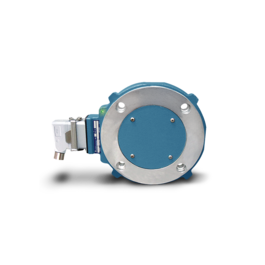

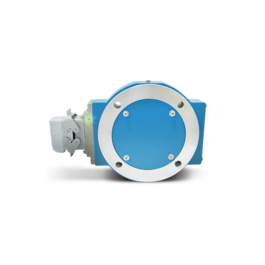

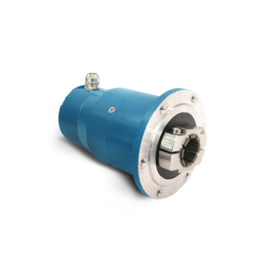

Encoders

Safe & Reliable Encoders for your Application

Working in process factories will be easy and safe with our products for heavy and light mill industries!

We provide a wide range of magnetic encoders to various heavy and light mill applications. Our encoders have the option to have a solid shaft or through bore mount depending on usage and application. All encoders are of high IP-rating which mean they can handle harsh environments, such as dust, vibration, oil, cold or hot temperatures.