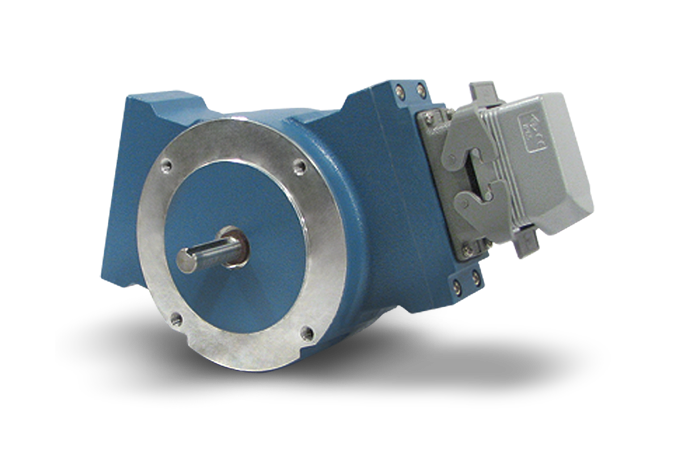

Explosion Safe Encoders

The modular incremental quadrature rotary encoders are a breakthrough in hazardous duty encoders to fit large shaft applications. They are ATEX/IECEx and cULus approved and offer incredibly reliable no-bearing construction!

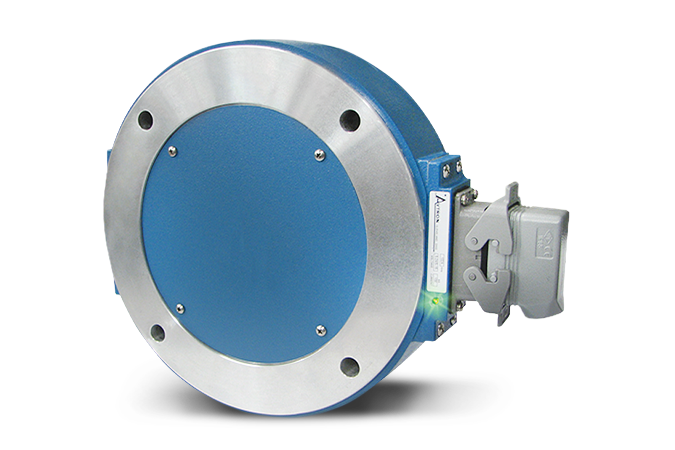

Heavy Mill Duty Encoders

Our heavy mill duty modular magnetic encoders fit up to standard 12.5" C-Face motors and 12.5" flanges commonly used for NEMA brake mounting.

Light Mill Duty Encoders

Our light mill duty modular magnetic encoders are cost efficient and easy to install. Did you know Bullseye32™ (AV32) encoders eliminate the top culprits that cause encoder failures: there are no bearings...