Cleaning Systems

Used in factory automation

Meeting the challenges of limited space and high outputs, Our solutions for bottle washing and cleaning systems address each project's requirements delivering reliable and efficient container cleaning prior to liquid filling, capping, labeling and other packaging line phases.

We offer specialized high-performance fluid rotary union and rotary timing valve products designed for transferring steam, water, air and other media types. These components can be combined with electrical slip rings for signals transmission over 360°. We can also provide COTS drives.

Flowpack Systems

Used in Factory Automation

The new generation Flowpack machines must combine flexibility and reduced costs; we can offer solutions for these systems together with Penlink's sister companies. By providing a complete package, from HMI and PLC to the servomotors based on EtherCAT Fieldbus.

We provide solutions for the rotary transmission such as encoders and electrical slip rings! Our wide assortments of drives can also help you with the motion control! Get in touch to know more!

Palletizing Applications

Used in factory automation

We provide a wide range of electrical slip rings to various palletizing applications. The slip ring can transfer data, signal, power and we can modify standard solutions to fit your application!

In modern palletizing systems the motion control has become more advanced, static positioning to dynamic motion control acting as an industrial robot, we have the motion control solution for you!

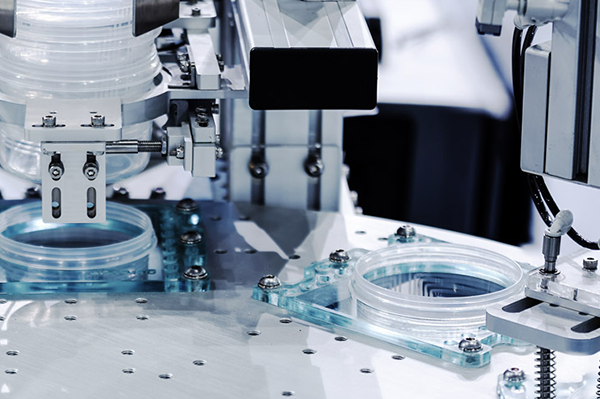

Rotary Filling Systems

Used in factory automation

Together with our partner DSTI, our sealing solutions for rotary filling equipment provide dependable fluid transfer for a wide range of viscosity. Our rotary joint (manifold) products are customized for each unique liquid filling application and incorporate high-performance seals, material and plating for advanced protection against corrosion providing superior performance and extended service life. These solutions can be designed to be easy to integrate and compliance with FDA.

Did you know we can integrate the fluid rotary union with an electrical slip ring?

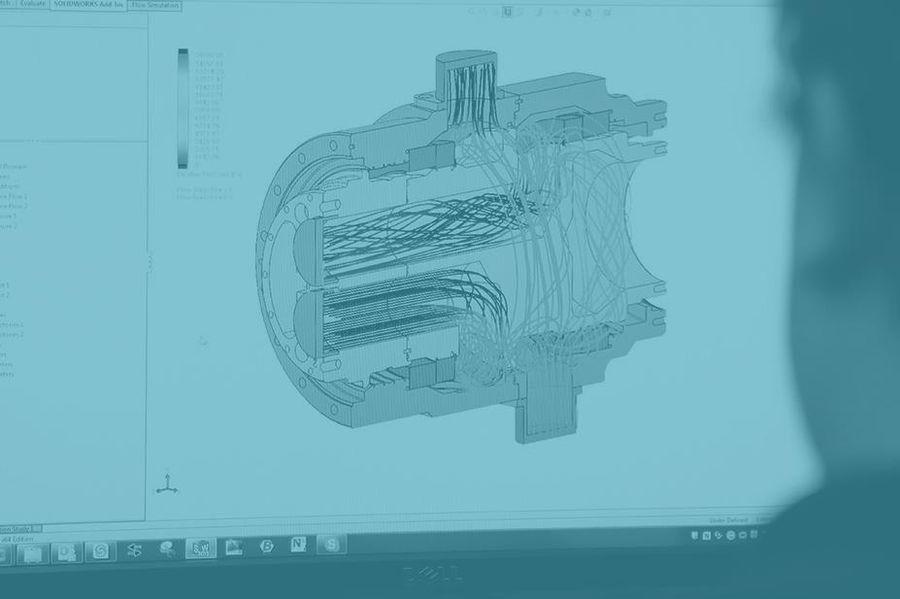

Rotary Table

Used in factory automation

Reliable supply and flow control of hydraulics and pneumatics are critical for clamping operations. We offer high-precision rotary union solutions for continuous flow and rotary timing valve solutions for controlling flow to meet the exact fluid, operating pressure, speed, and the space requirements of each unique workholding application.

Many of these applications also require electrical power and signals transfer which is solved by using an electrical slip ring. We can also help out with accurate positioning and motion control!

Contact us for more Solutions

Learn more

Can't find the right solution for your project under Factory Automation, please contact us and we can help you. We have done multiple projects and solutions for applications that might not be listed here.