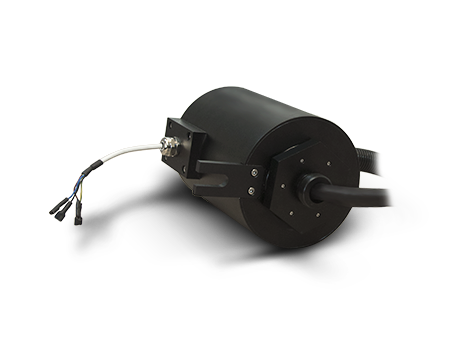

Electrical Slip Rings

We have a wide range of standard, modified and customized solution. We can modify anything you need for your product and application.

Rotary Unions

Our rotary unions reliably sealed and can transfer fluid such as water, air, hydraulic oil, coolant and other media types from stationary sources to rotating parts.

Fiber Optical Rotary Joints

The Fiber Optical Rotary Joint (FORJ) allow for uninterrupted transmission of optical signals while rotating around their shaft. Our components are the best on the market.

Integrated Solutions

Penlink has the capability to provide the services of integrated rotary joint solutions! These integrated solutions can be designed based on a sketch or an idea...

Cable Reels

Motorised cable reels provided by Penlink are technologically advanced and sturdily designed – for both continuous operation in ports and container terminals.

RF Rotary Joint

We offer non-contacting rotary joints that are extremely long-lived, they are also available as coaxial and waveguide units.

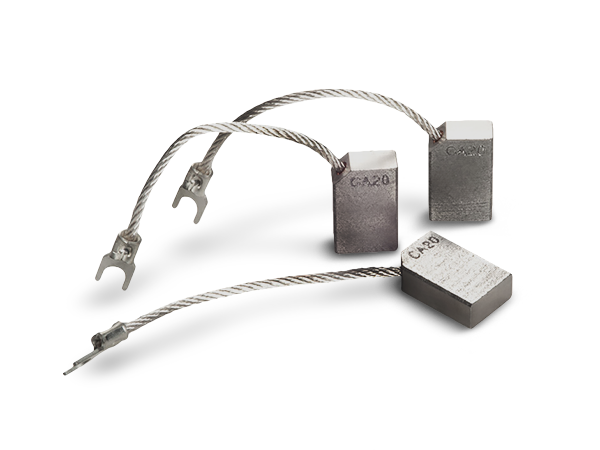

Brushes for Slip Rings

We can develop and manufacture wind power carbon brushes in copper and silver designed for use in extreme environments.

Not sure what you're looking for, don't hesitate to get in touch with us.

We will help you figure out what solution you need for your application.

We have wide range knowledge of applications and products in the electro mechanical components, electro optics & servo system industry.